ROBOTIC MATERIAL HANDLING

NEW to Robotics and Automation? We have simple, affordable solutions HERE

AUTOMATE YOUR TASKS

Increase efficiency of your processes with a robotic material handling system. Repetitive tasks can be strenuous on your employees, especially if your products are heavy and awkward. Common applications include:

Pick & Place

Palletizing

Press Tending

Machine Tending

Sheet Stacking

Assembly

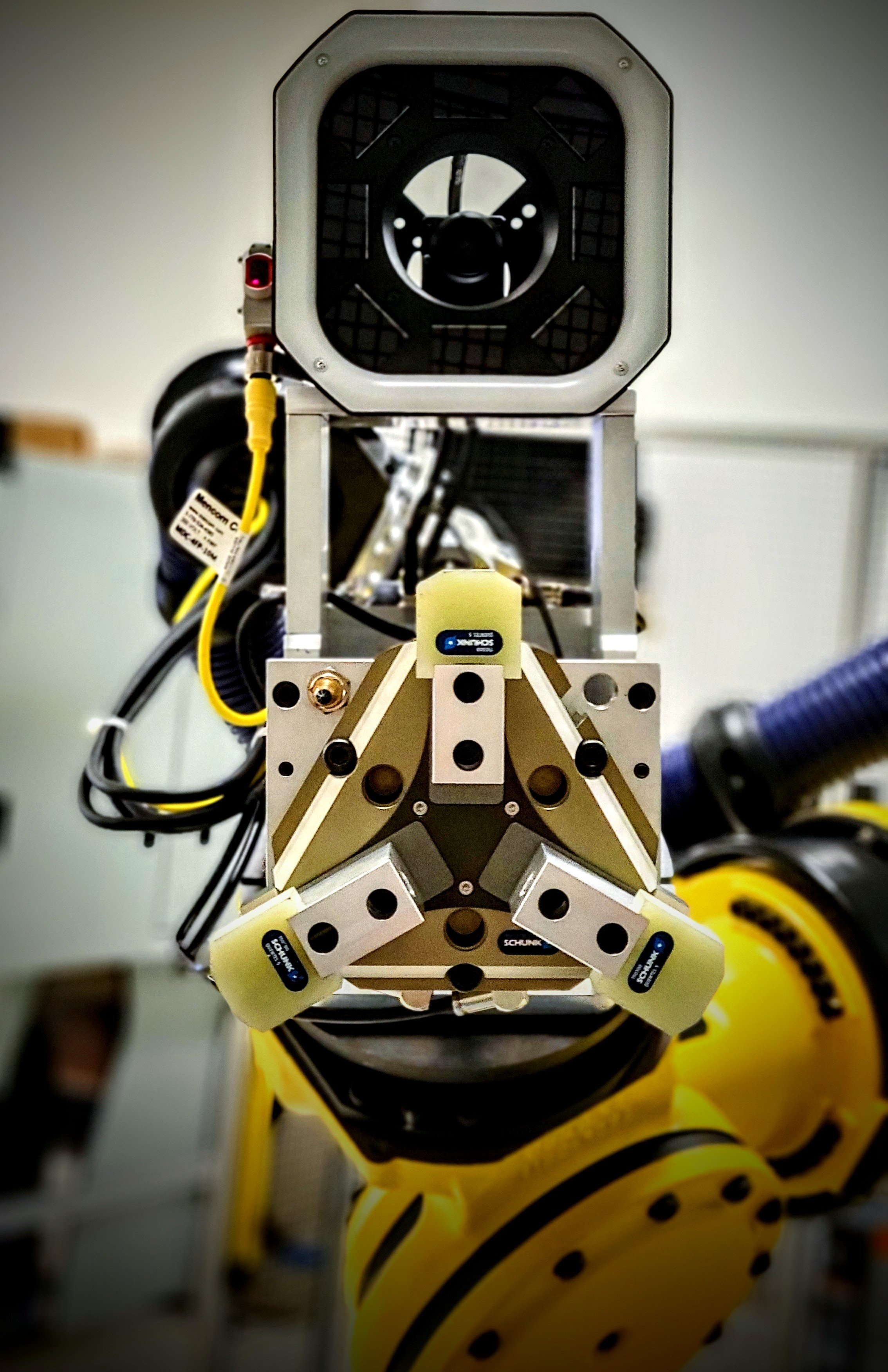

MACHINE TENDING

Robotic Machine Tending is one of the most popular applications for using a robot. Alliance Automation integrates robots which can communicate with your existing machining center to load and unload parts.

PRESS TENDING

Robotic Press Tending increases worker safety by removing the operator from the press area. Robots can consistently load and unload various types of presses with accuracy. Alliance Automation integrates robots which communicate with your existing machines.

COLLABORATIVE ROBOTS

Material handling is often a good application to consider collaborative robots for small, simple tasks. These types of robots don’t require the traditional safety guarding.

TURNING CONCEPTS INTO REALITY

Alliance Automation specializes in using CAD data to create a realistic concepts of your material handling applications. Cycle time and overall feasibility are estimated more accurately allowing you to be confident in calculating ROI.

The end of arm tooling can make all the difference.

Customer parts are not all the same and often need custom solutions. Let us help design the correct end of arm tooling for your application.

STAY CONNECTED